Sustainability

Upco's commitment to a sustainable future is reflected in the attention paid by the company to central issues such as: the implementation of production processes designed to limit emissions and consumption, the development of eco-sustainable products and the feasibility study of a closed loop recycling project (i.e. circular economy) that the company is carrying out together with scientific and industrial partners.

In 2023 Upco, together with the parent company Coveme, also completed its first sustainability report and in 2024 it calculated the company carbon footprint (CFP), scopes 1,2,3, according to the GHG Protocol.

1. Sustainable production processes:

Clean room

Upco's production line works in a protected environment, so-called "clean room", which means that the level of particles suspended in the air is strictly controlled and kept at low levels through the regulation of temperature, humidity and filtration of the air.

Solvent-free

Furthermore, during the production process, no solvents are used and this leads to a significant reduction in harmful emissions associated with the use of solvents.

2. Recycled and recyclable products:

Upco has studied and developed various sustainable solutions for the products in its range.

Green product

The range of Upco films has a reduced environmental impact thanks to the innovative solvent-free coatings used, free of harmful chemical substances such as chromium, formaldehyde and phthalates, which are processed with radiation curing technologies.

For these reasons the films in the Upco range are entirely recyclable at the end of their life cycle , 100% recyclable.

Recycled Product

Upco is the first manufacturer of release films to offer a range of products made of recycled polyester (rPET), coming from the post-consumer recycling of plastic bottles, food trays, etc.

The Upco ECO product range, composed of 70% rPET, has the same mechanical and physical properties as virgin PET and guarantees the same performance as standard products.

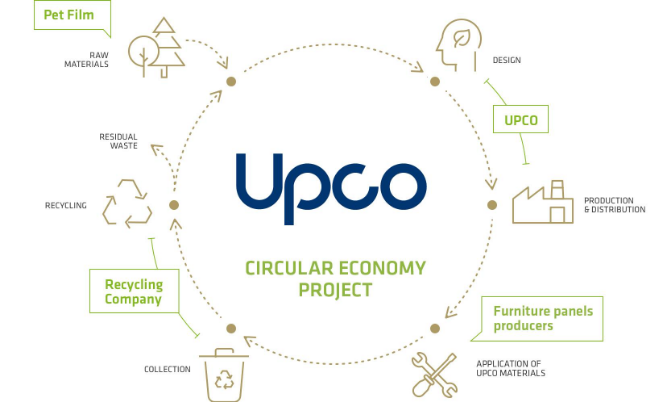

3. Circular Economy Project:

Thanks to partnerships with suppliers, scientific partners and recycling companies, Upco has demonstrated the feasibility of closed loop recycling for its release films. After use, Upco films can be recycled through an innovative Monomer Recycling process, with the possibility of upcycling, in order to produce new PET (rPET) film with the same chemical-physical characteristics of virgin PET.

It is expected that in 2024 the pilot project will be launched on an industrial scale, first using Upco's internal waste and subsequently using that of our customers.

4. Sustainability report

Since 2022, the Coveme Group, of which Upco is a part, has been publishing the Group's sustainability report, driven by the awareness that sustainability today represents a central element for a company's success.

The sustainability report is important because it offers a complete picture of a company's activities and performance, paying attention to the balance of economic, social and environmental aspects in order to create long-term value for the company and for future generations. Upco was supported in this project by Hidra, a benefit company, specialized in consultancy for sustainable strategic innovation.

5. Company Carbon Footprint

Coveme group, which Upco is part of, calculated the Carbon Footprint (CFP) by measuring the greenhouse gas (CO2) emissions generated by the company through a shared international standard, the GHG Protocol. Group's emissions have been calculated in 3 different scopes or areas:

Scope 1: includes all direct emissions of the company

Scope 2: includes indirect emissions associated with the purchase of electricity

Scope 3: includes all indirect emissions that occur along the company's value chain, both upstream and downstream of the organization.

From the measurement of emissions (CO2) of the Coveme group, according to the GHG Protocol, it emerged that in 2023 the emissions deriving from scopes 1 and 2 represent 11%, while those deriving from scope 3 represent 89% of the total.

Within scope 3 the most significant item concerns the purchase of raw material, i.e. polyester film. Coveme gruop, which already offers a range of recycled PET (rPET), will focus even more on this theme by pushing the offer of eco-sustainable materials.

Thanks to a detailed mapping of emissions it will now be possible to implement a medium and long-term Strategic Sustainability Plan.

6. Instructions for the correct disposal of packaging:

At Upco, all the packaging of the goods shipped is provided with a QR code which contains information on the type of packaging in order to facilitate the disposal of the different types of materials.

Upco is ISO 14001:2015 certified for environmental management